The ClickCorner by Nefab revolutionizes the sheet box packaging industry

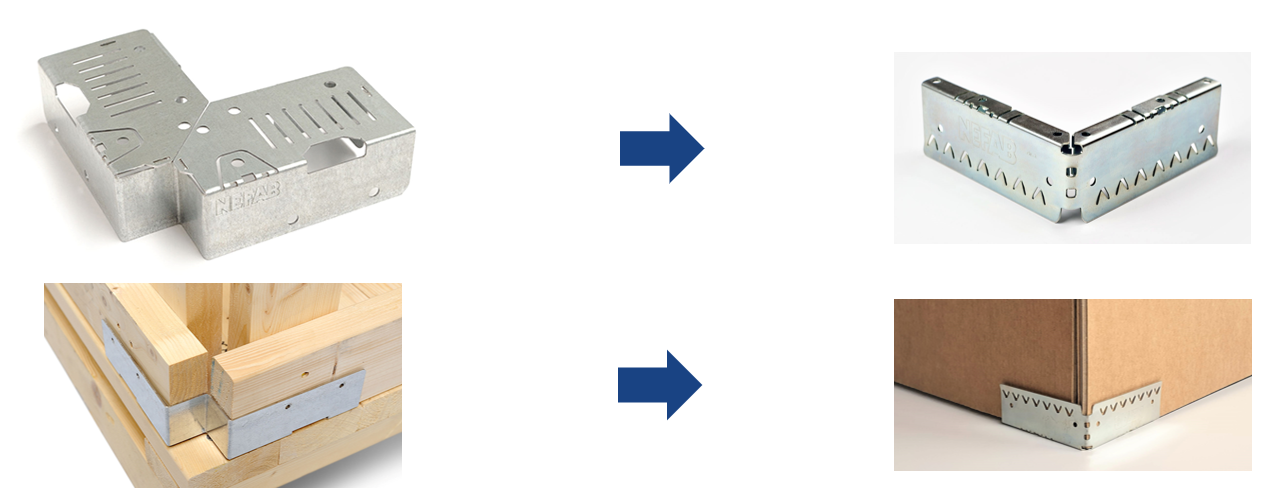

The latest edition to the sheet box packaging industry is the ClickCorner from Nefab. Introduced in December 2019, the ClickCorner has already established a solid position in the market. It forms a welcome addition to CratePak-O HD and the ExPak packaging solutions from Nefab.

Whereas the CratePak-O HD is perfect for the construction of large sheet boxes, the ClickCorner is ideal for quickly connecting smaller sized sheets. The ClickCorner has a couple of noteworthy packaging properties which provide an all-in-one solution for sites that lack the time or equipment to work with the CratePak-O HD.

The ClickCorner from Nefab

- Allows you to quickly produce boxes in any size and quantity;

- Eliminates the need for additional mounting materials;

- Does not require heavy-duty machinery. A plotter or saw table will suffice;

- Provides an extremely solid grip on the corners;

- Ensures full protection of the corners;

- Has a built-in fixation for bottom and lid sheets;

- Optimizes end-of-life material separation;

- Could be considered reusable, hence greatly improving its lifetime value;

- Is thoroughly tested and complies with the latest ISTA norms for transport and logistics.

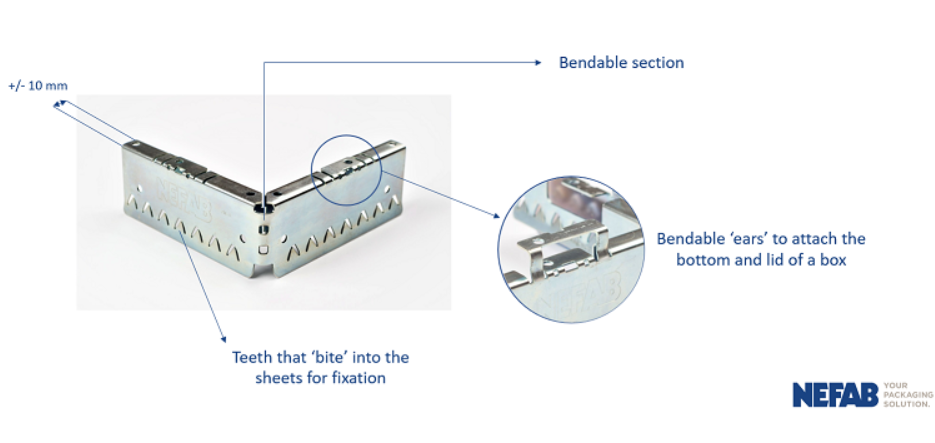

The ClickCorner explained

The ClickCorner originated from the need for efficient packaging solutions at smaller sites with limited equipment. As stated by Hans Nelen (Technical Sales Engineer at Nefab Benelux) “We noticed the need for a quick and cost-effective packaging solution for smaller quantities of sheet boxes. Industries such as defense, tech and pharmaceutics could benefit greatly from this solution as they often do not have the time nor the equipment to build large sheet box packaging”.

The product properties of the ClickCorner perfectly embody these requirements.

The product properties of the ClickCorner

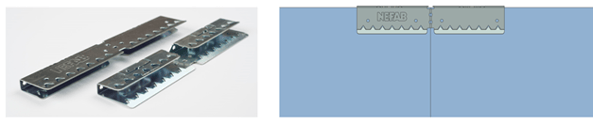

- The ClickCorner is made of Galvanized steel plates. These provide enhanced strength and rigidity for the rough shipping conditions it has to endure;

- The clip is capable of holding sheets between 8mm and 11mm. These dimensions are in line with common industry standards;

- The incorporated teeth are developed to attach themselves to the sheet for additional fixation;

- The addition of the bendable ‘ears’ allow for a lid to be attached to the top or bottom.

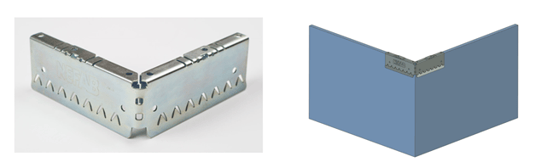

The versatility of the ClickCorner also shows in its applicability.

- The bend-form for easily constructing a sheet box:

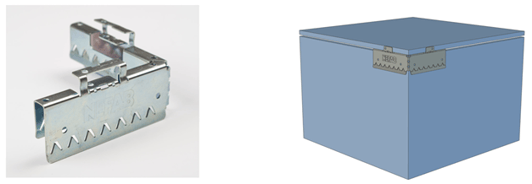

- The ‘ears-up’ form for attaching a top or bottom to the sheet box

- The flat form for connecting two sheets and creating bigger boxes:

- To prevent bulging on the sides of larger boxes:

The ClickCorner: end of life recycling

In addition to the standard ClickCorner, Emma Goetheer, a colleague of Hans also developed the Clippie and a foldable channelplate box. These addons for the ClickCorner both aim at improving end of life recycling and encourage interim storage. Hans stated “I’ve been testing the reusability of the ClickCorner myself and I must say I’m thrilled with the results. Even after folding the ClickCorner for more than 30 times, it still maintains its intense grip and protective capabilities. This is also why I developed the ClickCorner and the foldable channelplate box. Both options greatly improve the reusability of the ClickCorner by allowing for easy removal. It completely eliminates the need for long and expensive end of life recycling and encourages interim storage”.

How does the ClickCorner work? (video)

How does the foldable channelplate box work? (video)

Order the ClickCorner for your company

Interested in the Clickorner possibilities for your company? Or global supply, testing or sheet box packaging (design) in general? Get in touch today! Our Nefab sales engineers are keen to introduce your company to the next level of sheet box packaging.

Gepubliceerd door Emiel Van Dijk op 1 juli 2020